|

NINGBO DINGDANG NEW MATERIAL TECHNOLOGY CO., LTD.

|

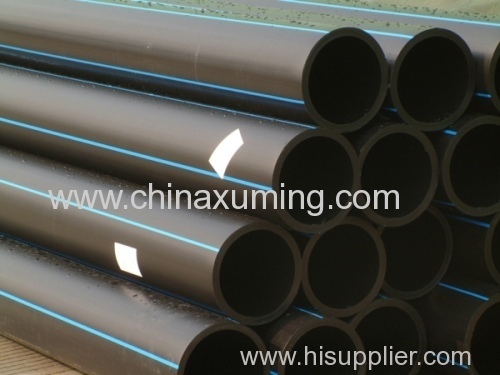

HDPE Pipes With PE80 for Water and Gas

| Price: | 0.5~500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Using German production line;

100% imported raw material;

Implementation of ISO quality management system standard

Suitable for water,oil and gas

HDPE Pipes With PE80 for Water and Gas

1.Application Areas:

> Municipal and industrial water transmission systems.

> Potable water service or distribution lines.

> Sewer piping systems.

> Pipeline rehabilitation.

> Slip lining.

> Natural gas distribution.

> Irrigation and landscaping

2.Product features

***Corrosion Resistance

HDPE pipes and fittings have excellent resistance against electrolytic or galvanic corrosion or any known corrosive soil or water condition. HDPE is also characterized by highly abrasion resistance.

***High Flow Capacity

HDPE pipes have a smooth internal surface which ensures less drag and a lower tendency for turbulence at highflow. Its superior flow characteristic eliminates scaling and pitting and guarantees consistent flow through out the pipe's entire service life.

***Low Installation Cost

HDPE pipes are lightweight,flexible,and produced in long lengths,which results in easier and convenient installation. The flexible nature of the polythylene pipes reduces the use of bends.

Alternate installation methods such as Directional Drilling,Pipe Building,Slip Lining,Plough and Plant,Submerged or Floating Pipe,etc. can save considerable time and money in most potable water applications.

***Easy Maintenance

CXM brand polyethylene pipes are maintenance free with a desigh life of over 70 years under normal operating conditions. PE pipes offer long-term resistance to avariety of service conditions such as:abrasion,temperature and soil movements,bending,weathering,internal pressure,direct burial,point loading and squeeze-off.

***Easy Handling

Polyethylene is about one-eighth the density of steel and thus does not require the use of heavy lifting equipment for installation.

***High Impact Strength

Polyethylene pipe is able to structurally withstand a higher impact than equivalent rigid pipes,especially during cold weather installations when other materials are more prone to cracks and impact failure.

Slow crack growth is the primary cause of most pipe failures and this is primarily investigated by third party damage during the installation process. The advanced polyethylene material used by XUMING INDUSTRY CO., LIMITED in its production process provides a highly resistance base to prevent fatigue and slow crack growth.

3.The mainly physical properties of HDPE pipes for water

| Item | Hoop strees (MPa) | Requirement | |

| PE80 | PE100 | ||

| 20ºC hydrostatic strength (100h) | 9.0MPa | 12.4MPa | No damage,No leakage |

| 80ºC hydrostatic strength (165h) | 4.6MPa | 5.5MPa | No damage,No leakage |

| 80ºC hydrostatic strength (1000h) | 4.0MPa | 5.0MPa | No damage,No leakage |

| Item | Requirement | ||

| Fracture and elongation | 350% | ||

| Longitudinal reversion (110ºC) | ≤3% | ||

| Oxidation induction time (200ºC) | ≥200min | ||

4.Specification of HDPE pipes for water

Out Diameter (mm) | SDR33 | SDR21 | SDR17 | SDR13.6 | SDR11 |

| Pressure: MPa | |||||

| 0.4MPa | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | |

| Wall Thickness (mm) | |||||

| DN25 | 2.3 | ||||

| DN32 | 3.0 | ||||

| DN40 | 3.7 | ||||

| DN50 | 4.6 | ||||

| DN63 | 5.8 | ||||

| DN75 | 4.5 | 5.6 | 6.8 | ||

| DN90 | 4.3 | 5.4 | 6.7 | 8.2 | |

| DN110 | 5.3 | 6.6 | 8.1 | 10.0 | |

| DN125 | 6.0 | 7.4 | 9.2 | 11.4 | |

| DN140 | 6.7 | 8.3 | 10.3 | 12.7 | |

| DN160 | 4.9 | 7.7 | 9.5 | 11.8 | 14.6 |

| DN180 | 5.5 | 8.6 | 10.7 | 13.3 | 16.4 |

| DN200 | 6.2 | 9.6 | 11.9 | 14.7 | 18.2 |

| DN225 | 6.9 | 10.8 | 13.4 | 16.6 | 20.5 |

| DN250 | 7.7 | 11.9 | 14.8 | 18.4 | 22.7 |

| DN280 | 8.6 | 13.4 | 16.6 | 20.6 | 25.4 |

| DN315 | 9.7 | 15.0 | 18.7 | 23.2 | 28.6 |

| DN355 | 10.9 | 16.9 | 21.1 | 26.1 | 32.2 |

| DN400 | 12.3 | 19.1 | 23.7 | 29.4 | 36.3 |

| DN450 | 13.8 | 21.5 | 26.7 | 33.1 | 10.9 |

| DN500 | 15.3 | 23.9 | 29.7 | 36.8 | 45.4 |

| DN560 | 17.2 | 26.7 | 33.2 | 41.2 | 50.8 |

| DN630 | 19.3 | 30.0 | 37.4 | 46.3 | 57.2 |

| DN710 | 21.8 | 33.9 | 42.1 | 52.2 | |

| DN800 | 24.5 | 38.1 | 47.4 | 58.8 | |

| DN900 | 27.6 | 42.9 | 53.5 | ||

| DN1000 | 30.6 | 47.7 | 59.3 | ||

We have 100,000 square meters of factory, including plastic injection workshop, mold workshop, CNC workshop, packaging workshop, raw material warehouse, finished products warehouse and office building.

The company has dozens of skilled researchers.

Welcome to our factory to visit.