|

NINGBO DINGDANG NEW MATERIAL TECHNOLOGY CO., LTD.

|

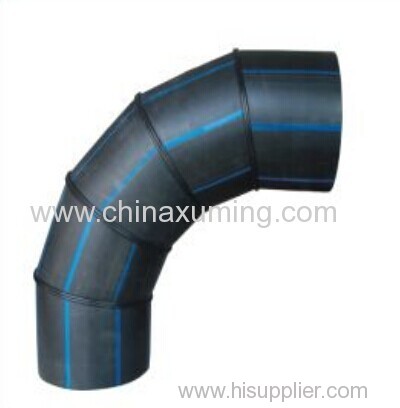

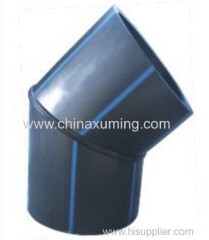

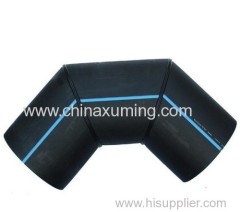

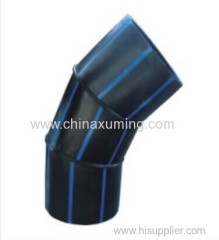

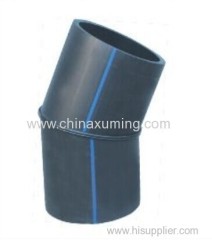

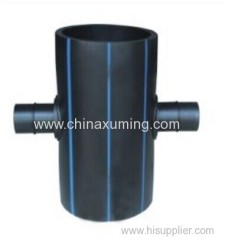

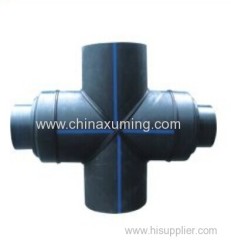

HDPE Fabrocated 90° Bends Pipe Fittings

| Price: | 1.0~500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

HDPE Fabrocated 90° Bends Pipe Fittings

Advanced welding process

Use large-scale multi-angle welding machine

Can be bear SDR17 pressure

HDPE Fabrocated 90°Bends Pipe Fittings

***Advantages and welding of PE butt fusion welding 90 degree elbow pipe fittings:

PE butt fusion welding 90 degree elbow pipe fittings is light, which is more common for partial

application pe80 pe100 grade level and two standards , including :

PE80 density of about 0.94 g / cm 3, PE100 density of about 0.96 g / cm 3 ;

Easy thermoplastic - easy to process ( such as injection molding, extrusion molding

Remanufacturing easy recycling

Good resistance to radiation and chemical stability

Good resistance to cold , the temperature can be -40 ℃ to +40ºC

Excellent electrical insulation properties , is not affected by electrolytic corrosion

Malleable - extended break PE80> 700% PE100> 600%

Anti- erosion resistance - 8 times better than steel

Approximately half of the low thermal conductivity of glass

Smooth surface , unlike the role of metal pipes rust easily with oxygen crusts

pe pipe connection into fused pipe connections and fittings connected to melt , the more ordinary side,

the other , as well as socket connections, this method is applied to a small size.

1 , fused connection : Follow these steps: First check , and then is cut pipe , pipe fittings joints clean , scrape the oxide layer , connecting the two parts of the tube and pipe fittings , calibration welder , welding parameter adjustment in accordance with the welding voltage, welding Dimensions , electricity, welding, and then finally cooled.

2, the hot melt connection : the inner surface of the pipe surface and the pipe is inserted while the welding is non-rotating die head is heated for a few seconds , then quickly removed and welding device , the heat pipe has a fast vertical insertion tube , packing, cooling to .

3 , socket connections, relatively simple, not elaborate here .

***Specifications of hdpe butt weld 90 degree elbow with five segments pipe fittings:

| |||

| Size | D(mm) | H(mm) | L(mm) |

| L500 | 500 | 1055 | 350 |

| L560 | 560 | 1145 | 380 |

| L630 | 630 | 1326 | 440 |

| L710 | 710 | 1447 | 480 |

| L800 | 800 | 1507 | 500 |

| L900 | 900 | 1658 | 550 |

| L1000 | 1000 | 1808 | 600 |

| L1200 | 1200 | 1959 | 650 |

***Basic performance of raw materials for pipe fittings

| Paramenter | Units | Requirement | Test Value |

| Density | kg/m³ | ≥930 | 23ºC |

| Melt flow rate | g/10min | 0.2~1.4 | 190ºC,5kg |

| Thermal slaility (OIT) | min | >20 | 200ºC |

| Volati lematter content | mg/kg | ≤350 | |

| Moisture content | mg/kg | ≤300 | ASTM D 4019:1994a |

| Carbon black content | % | 2.0~2.5 | |

| Crbon black dispersion | grade | ≤3 | |

| Gas proof components | h | ≥20 | 80ºC,2MPa(Hoop stress) |

Resistance to slow crack growth (En>5mm) | h | 165 | 80ºC,0.80MPa(Testing pressure) 80ºC,0.92MPa(Testing pressure) |

***Performance requirement of pipe fittings

| NO. | Item | Requirement | Test value |

| 1 | 20ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 10.0MPa PE100 12.4MPa Testing temperature: 20ºC Testing time: ≥100h |

| 2 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥165h |

| 3 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥1000h |

| 4 | Tensile strength of butt-fusion pipe fittings | Test to destruction: Flexible is good | Testing temperature:23ºC±2ºC |

| 5 | Welding strength of electro-fusion | Percentage of brittle peel: ≤33.3% | Testing temperature:23ºC±2ºC |

| 6 | Oxidation induction time | >20min | 200ºC |

| 7 | Melt flow rate | Tube melt rate of change not exceeding ±20% of the raw material | 190ºC, 5kg |

***hdpe butt welding machine

***Exporting countries