|

NINGBO DINGDANG NEW MATERIAL TECHNOLOGY CO., LTD.

|

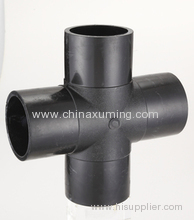

HDPE Thermweld Post Frming Reducer Pipe Fitting

| Price: | 1.0~500.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Imported high quality raw material

Butt fusion post forming

Can meet customers' request and need

Equipment: plastic injection machine

HDPE Butt Fusion Post Forming Redecing Coupling Pipe Fittings

***Specifications

| |||||

| Size Dxd | Size Dxd | Size Dxd | Size Dxd | Size Dxd | Size Dxd |

| S355x110 | S355x160 | S355x180 | S355x200 | S355x225 | S355x250 |

| S355x280 | S355x315 | S400x110 | S400x160 | S400x180 | S400x200 |

| S400x225 | S400x250 | S400x280 | S400x315 | S400x355 | S450x110 |

| S450x160 | S450x180 | S450x200 | S450x225 | S450x250 | S450x280 |

| S450x315 | S450x355 | S450x400 | S500x160 | S500x200 | S500x225 |

| S500x250 | S500x280 | S500x315 | S500x355 | S500x400 | S500x450 |

| S560x160 | S560x200 | S560x225 | S560x250 | S500x280 | S560x315 |

| S560x355 | S560x400 | S560x450 | S560x500 | S630x160 | S630x200 |

| S630x225 | S630x250 | S630x280 | S630x315 | S630x355 | S630x400 |

| S630x450 | S630x500 | S630x560 | S710x200 | S710x250 | S710x315 |

| S710x355 | S710x400 | S710x450 | S710x500 | S710x560 | S710x630 |

| S800x200 | S800x250 | S800x315 | S800x355 | S800x400 | S800x450 |

| S800x500 | S800x560 | S800x630 | S800x710 | S900x250 | S900x315 |

| S900x355 | S900x400 | S900x450 | S900x500 | S900x560 | S900x630 |

| S900x710 | S900x800 | S1000x250 | S1000x315 | S1000x355 | S1000x400 |

| S1000x450 | S1000x500 | S1000x560 | S1000x630 | S1000x710 | S1000x800 |

| S1000x900 | S1200x250 | S1200x315 | S1200x355 | S1200x400 | S1200x450 |

| S1200x500 | S1200x560 | S1200x630 | S1200x710 | S1200x800 | S1200x900 |

| S1200x1000 | |||||

***Performance requirement of pipe fittings

| NO. | Item | Requirement | Test value |

| 1 | 20ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 10.0MPa PE100 12.4MPa Testing temperature: 20ºC Testing time: ≥100h |

| 2 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥165h |

| 3 | 80ºC hydrostatic strength | No damage, no leakage | Hoop stress: PE80 4.50MPa PE100 5.40MPa Testing temperature: 80ºC Testing time: ≥1000h |

| 4 | Tensile strength of butt-fusion pipe fittings | Test to destruction: Flexible is good | Testing temperature:23ºC±2ºC |

| 5 | Welding strength of electro-fusion | Percentage of brittle peel: ≤33.3% | Testing temperature:23ºC±2ºC |

| 6 | Oxidation induction time | >20min | 200ºC |

| 7 | Melt flow rate | Tube melt rate of change not exceeding ±20% of the raw material | 190ºC, 5kg |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!